Connect with Collabtec Design Build Pvt Ltd+91810485903 for Pharmaceutical clean room design services.

Pharmaceutical clean room design services

collabtechdb

Specialities

Sectors Served

Service Models

Innovative Architectural Design

Adaptable Building Services (MEP)

Frugal Engineering for optimized CAPEX & OPEX

Sustainable Design Strategies

Extended onsite team for construction

Health & Safety

Bill Certification & Budget Control

Qualification & Validation services

Complete Technical Ownership &Success

Single Point Responsibility

Faster Project Delivery

Guarantee on Pricing

Advantage Collabtec

Single Point Reliability

- Experienced team of Architects & Engineers

- Integrated Project Delivery

- Inhouse MEP expertise

BIM &3D Engineering Platform

- Clash Detection

- Excellent BOQ Accuracy

- Realtime 3D View

Safety of Men,Material &Data

- Vital inputs from EHS experts

- Process Safety Experts

GMP | GLP | GDP

- Good Manufacturing Practices

- Good Laboratory Practices

- Good Distribution Practices

our valued clients

Pharmaceutical cleanroom classification services

Cleanroom validation services in hvac

Cleanroom validation services near me

Cleanroom validation services cost

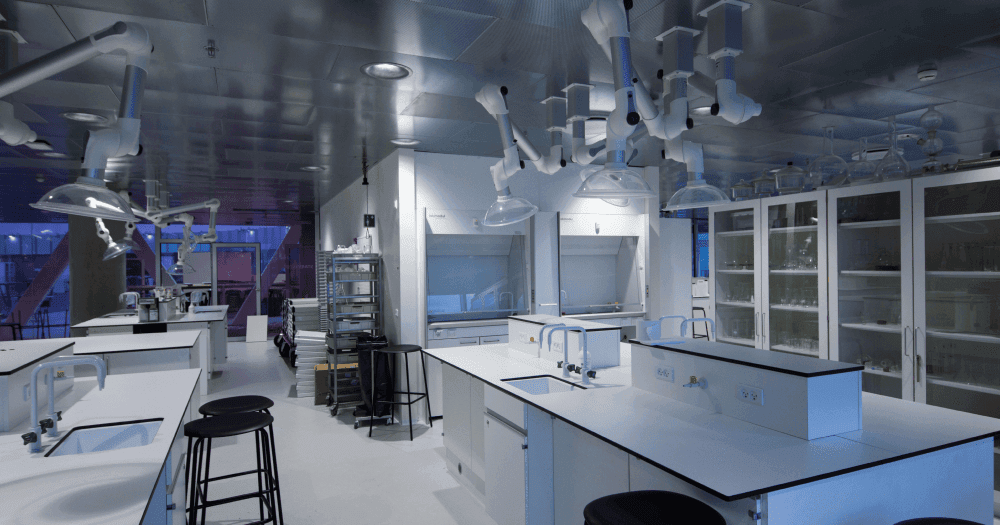

In the pharmaceutical and chemical industries,product integrity,safety,and regulatory compliance are non-negotiable. Central to achieving these goals is the design and validation of cleanrooms that meet stringent industry standards. For companies in need of world-class best pharmaceutical clean room design services – Collabtec stands as a trusted engineering partner.

With years of expertise in delivering GMP cleanroom design services,Collabtec ensures robust solutions tailored to the complex demands of pharmaceutical manufacturing. This article explores the essentials of pharmaceutical cleanroom design,classifications,validation services,and why choosing the right partner matters.

Understanding Pharmaceutical Clean Room Design

A cleanroom is a controlled environment where contaminants like dust,airborne microbes,aerosol particles,and chemical vapors are kept within strict limits. In the pharmaceutical sector,such spaces are critical during formulation,filling,packaging,and testing processes.

Why Pharmaceutical Cleanrooms Matter

Cleanrooms:

Protect drug formulations from contamination

Ensure safety for consumers

Are a regulatory requirement under GMP (Good Manufacturing Practice)

Enhance product shelf-life and reduce product recalls

Pharmaceutical Cleanroom Classification Services

Cleanrooms are classified based on the number of particles per cubic meter at a specific particle size. The commonly used standards include ISO 14644-1 and EU GMP guidelines.

ISO Classes:

ISO 5 (Class 100):For high-risk operations like sterile filling

ISO 7-8:Common for less critical manufacturing zones

EU GMP Grades:

Grade A:High-risk operations (aseptic preparation)

Grade B:Background for Grade A operations

Grade C &D:For less critical stages

Collabtec provides pharmaceutical cleanroom classification services that guide your facility in selecting the right class for each zone. Our engineering team ensures that HVAC systems,material flow,and personnel movement are aligned with the classification,keeping your facility audit-ready.

Elements of GMP Cleanroom Design Services

Designing a GMP-compliant cleanroom involves a strategic blend of architecture,engineering,and process knowledge. Collabtec’s GMP cleanroom design services include:

1. Layout Planning

Zoning based on contamination risk

Segregated personnel and material flow

Gowning and degowning areas

2. HVAC System Design

Temperature,humidity,and pressure control

Air changes per hour (ACH)

Laminar airflow and HEPA filtration

3. Material and Surface Selection

Smooth,non-shedding,and easy-to-clean surfaces

Cove joints for wall-floor and wall-ceiling intersections

4. Lighting and Automation

LED-based lighting solutions for energy efficiency

Integration with SCADA/BMS for monitoring

5. Documentation and Compliance

DQ/IQ/OQ/PQ documentation

Assistance with regulatory audits

Our team works closely with clients to deliver turnkey solutions—from concept to commissioning—ensuring compliance with WHO-GMP,USFDA,MHRA,and EU standards.

Cleanroom Validation Services in HVAC

Cleanroom performance is heavily dependent on its HVAC system. The validation of this system is essential to maintain cleanroom integrity.

Collabtec’s HVAC Validation Includes:

Airflow pattern testing

HEPA filter integrity testing (PAO/DOP test)

Temperature and humidity uniformity checks

Differential pressure measurements

Particle count monitoring

Our cleanroom validation services in HVAC are backed by calibrated instruments and seasoned professionals who understand the nuances of pharmaceutical processes. Whether you need an initial system validation or periodic revalidation,we ensure your systems are performing as intended.

Cleanroom Validation Services Near Me:Nationwide Reach

Collabtec operates across India with a rapidly growing portfolio of pharmaceutical and chemical clients. Whether you’re in Hyderabad,Mumbai,Ahmedabad,Pune,Bangalore,or Chennai,you can rely on our cleanroom validation services near me.

We offer both on-site validation services and remote consultation,ensuring flexibility and prompt service delivery. Our proximity to industrial zones and life sciences hubs makes us a reliable partner for quick deployment and service execution.

Cleanroom Validation Services Cost:#fff0 and Competitive

Cost is often a determining factor when selecting a cleanroom validation partner. At Collabtec,we believe in delivering value-driven engineering services. Our cleanroom validation services cost is competitive,tailored to your facility’s size,class,and process complexity.

We offer:

Flexible pricing models (project-based or AMC)

Detailed cost breakdowns (no hidden charges)

Custom packages for startups and SMEs

Collabtec is committed to making GMP-compliance affordable without compromising on quality.

Why Choose Collabtec?

Here are just a few reasons why pharmaceutical and chemical companies choose Collabtec:

✅ Expertise in Regulated Industries

Our engineering teams have deep domain expertise in pharma,biotech,and chemical sectors.

✅ End-to-End Service

From concept design,architectural layout,HVAC engineering,utility piping,to cleanroom furniture—we handle it all under one roof.

✅ Regulatory Compliance Focus

We design with audits in mind. Our systems are built to meet USFDA,EU-GMP,WHO,and other regulatory standards.

✅ Innovation and Efficiency

We integrate energy-efficient systems and digital monitoring tools for future-ready cleanrooms.

✅ After-Sales Support

Our relationship doesn’t end at commissioning. We offer post-installation support,maintenance,and revalidation services.

Use Cases:Real-World Applications

Case Study 1:Injectable Manufacturing Facility

Client:Mid-size pharma company in Pune

Challenge:Designing Grade A and B zones with pressure cascade and cross-contamination prevention

Solution:Delivered a complete HVAC and cleanroom solution with continuous monitoring systems

Result:Passed EU GMP audit with no major observations

Case Study 2:Chemical API Plant in Gujarat

Client:Bulk API manufacturer

Challenge:High particulate matter due to powder handling

Solution:ISO 7 classified cleanroom with dust extraction systems and HVAC redundancy

Result:Improved yield and regulatory compliance

How to Get Started?

Whether you’re planning a new facility or upgrading an existing one,it’s never too early to speak with a cleanroom expert.

📞 Call Collabtec at+91 81048 5903

🌐 Visit:https://collabtecdb.com

Our consultants will understand your process requirements and provide a tailored cleanroom design and validation plan that aligns with your budget and timeline.

Frequently Asked Questions (FAQs)

Q1. What is the difference between ISO and GMP classifications?

ISO standards focus on airborne particulate levels,while GMP classifications consider risk-based zones and operations. Cleanrooms must often comply with both.

Q2. How often should cleanroom validation be performed?

It’s recommended to conduct initial validation,post-modification validation,and annual revalidation for pharmaceutical cleanrooms.

Q3. Are your services suitable for small-scale or startup pharma units?

Absolutely! We offer scalable cleanroom solutions suitable for both startups and large-scale manufacturers.

Q4. Do you provide only design or complete build services?

We offer Design+Build services—including civil work,HVAC,electrical,and validation—all managed under one contract.

Final Words

In the pharmaceutical world,the cleanroom is not just a room—it’s a guarantee of quality and patient safety. With regulations becoming increasingly stringent,partnering with a seasoned design and validation expert is critical.

Collabtec is your go-to provider for pharmaceutical cleanroom classification services,GMP cleanroom design services,and comprehensive cleanroom validation services in HVAC.

Our motto is simple:Design for compliance,build for performance. Let’s work together to ensure your cleanroom meets the highest standards of safety,efficiency,and regulatory excellence.